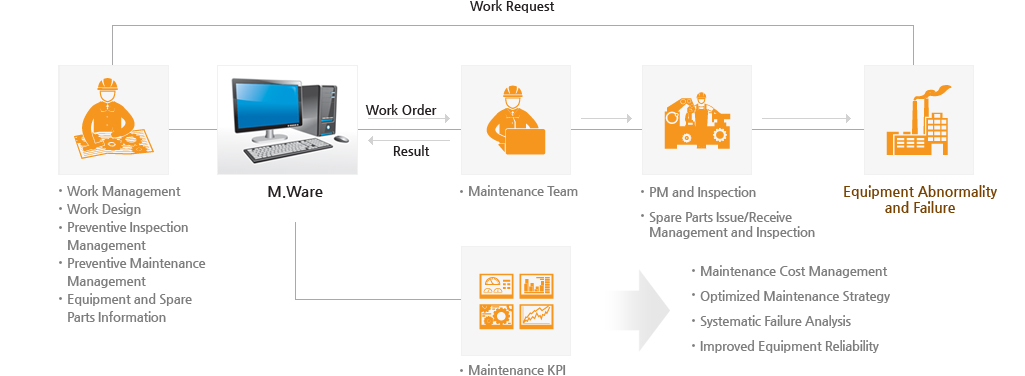

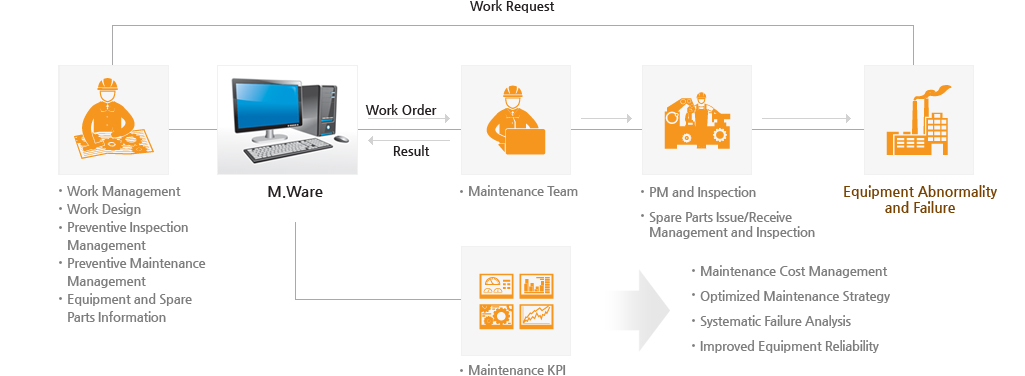

M.Ware is a web-based CMMS solution to computerize every activity of the maintenance department. M.Ware was developed using Dreamsoftware’s extensive experience and technical knowledge creating software solutions for various industries and applications. Modern automated manufacturing equipment is complex and widespread throughout large facilities . Businesses are finding it increasingly difficult to operate and maintain equipment in every location of a large facility. M.Ware enables stable operations and logical preventive maintenance by managing and providing accurate maintenance work process information.

Key Functions

주요기능

| Equipment Information |

- Equipment and user-centered equipment hierarchy by location, type and function

- Equipment specifications, maintenance histories, Bill of Materials (BOMs), work standards, technical documents, and drawings

|

| Work Management |

- Work Order issuing and history management, creating a preventive maintenance schedule, generate inspection and work requests

- Designing and planning maintenance work planning using work standards

|

| Preventive Inspection |

- The user defines and manages preventative inspection checks by type, period, items, and condition values, such as temperature, pressure, and

vibration status

- Generation of preventive inspection schedules

- Checks of closed inspection results and managing open inspection schedules

- Wireless maintenance inspections using MOBINS

|

| Preventive Maintenance |

- The user defines and manages maintenance work checks by, items, maintenance group or engineer, spare parts, and costs

- Preventive maintenance (PM) scheduling according to PM period *(TBM, UBM)

|

| Spare Part Management |

- Management of requesting, purchasing, receiving, and issuing spare parts

- Specific information for maintenance, such as spare part specifications, and receiving, issuing, and usage history

- Wireless spare parts management using MOBINS

|

| Maintenance Statistics |

Various maintenance statistics, such as number of failures, repair time, repair cost, equipment type, work type, number of repairs, and by failure symptom, cause, and action

|

| Global Integration |

- Enables integrated management of global information and KPIs

- Easy to apply and extend the system in future new factories

- Korean, English, and multi-language

|

* TBM: Time Based Maintenance

* UBM: Usage Based Maintenance

Case

- Implemented Global CMMS for Hyundai Dymos

- Implemented Global CMMS for Hankook Tire

- Implemented CMMS for OTTOGI

- Implemented CMMS for Hyundai Special Steel